Our Services

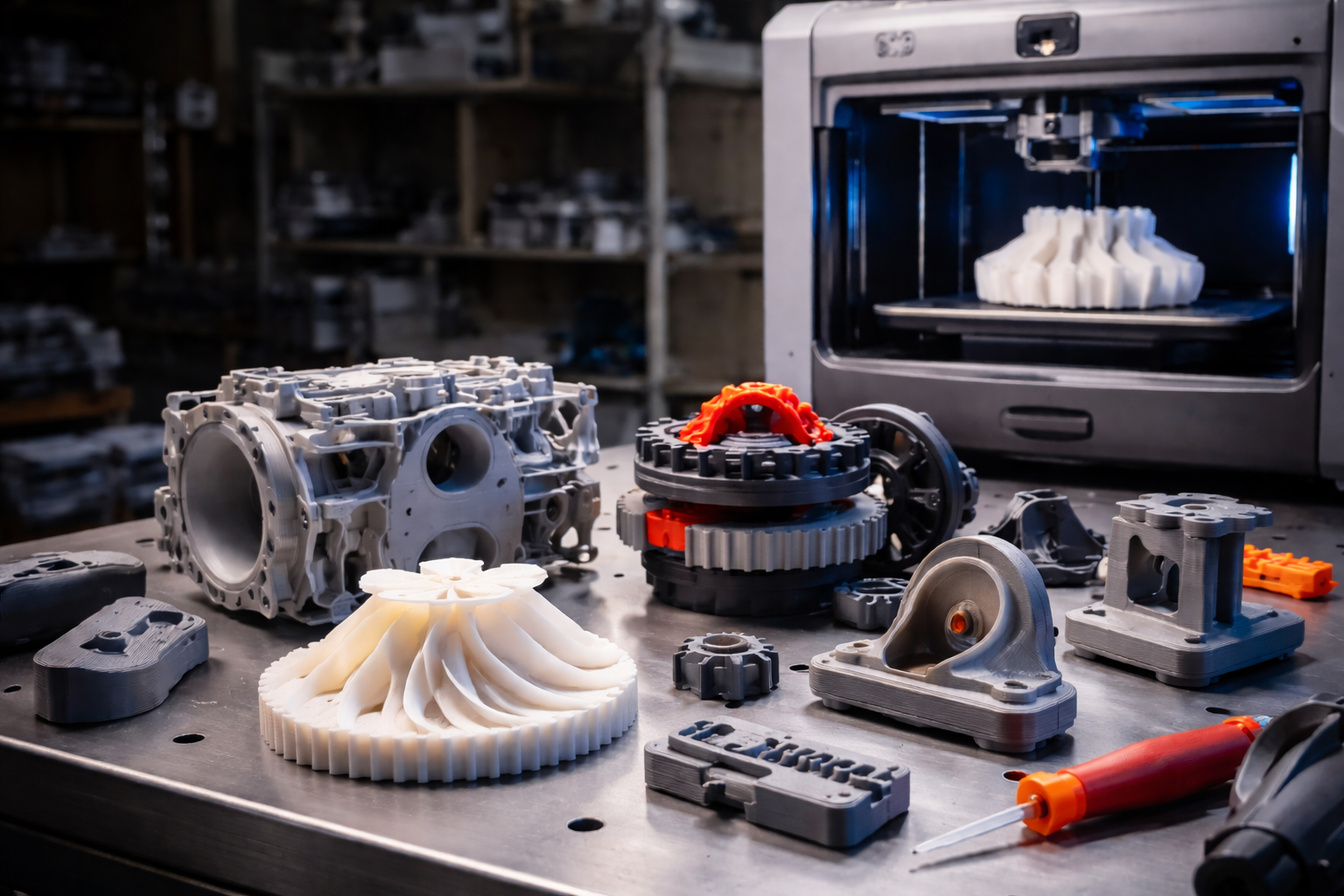

Engineering-Grade 3D Printing for Professional Applications

At Penrose 3D Ltd, we specialise in high-performance 3D printing services for businesses and individuals that require functional, reliable parts - not just hobby-grade models.

From single prototypes to repeatable batch production, we manufacture parts in engineering and industrial thermoplastics, all produced in the UK using professional-grade equipment.

We work closely with customers in automotive, robotics, automation, logistics, and motorsport, delivering components built for real-world use.

Prototype & One-Off Parts

Perfect for early-stage development, validation, and bespoke applications.

We produce high-accuracy prototypes and single-run parts that allow you to evaluate form, fit, and function before scaling to production. Where required, prototypes can be printed using the same materials intended for final use, providing realistic performance data.

Typical use cases include:

Functional testing

Fit and clearance checks

Design validation

Bespoke or low-volume components

Ideal for engineers, designers, and R&D teams who need fast turnaround without compromising material performance.

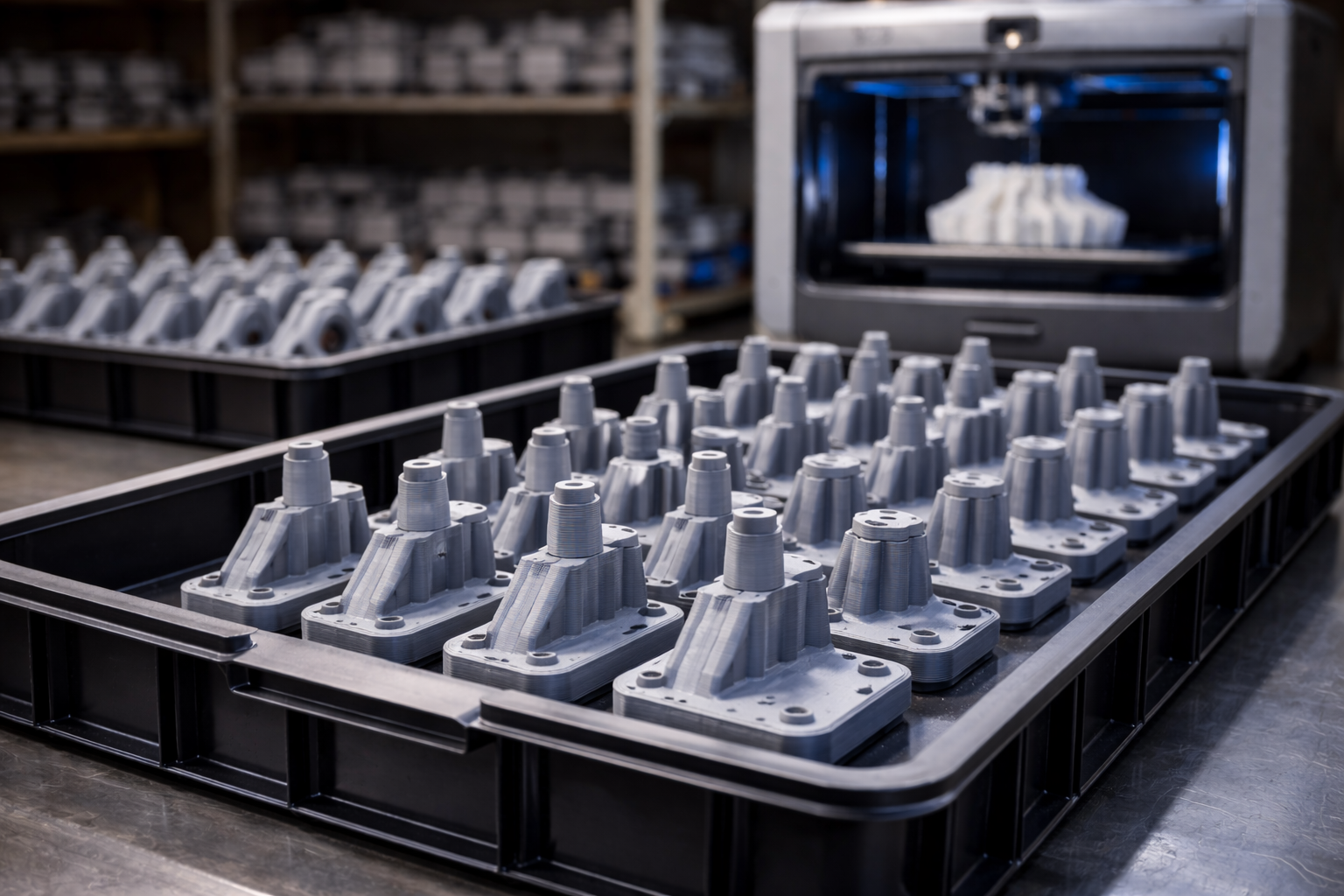

Batch Production

Low-to-medium volume production runs with consistent quality and repeatability.

Batch production is ideal when injection moulding is not viable due to cost, lead time, or design flexibility. We offer repeatable manufacturing, controlled print profiles, and consistent materials to ensure parts meet specification across every run.

Common applications:

End-use components

Jigs, fixtures, and tooling

Replacement or legacy parts

Small production assemblies

Batch sizes can range from small repeat orders to ongoing production schedules, with scalable capacity as demand grows.

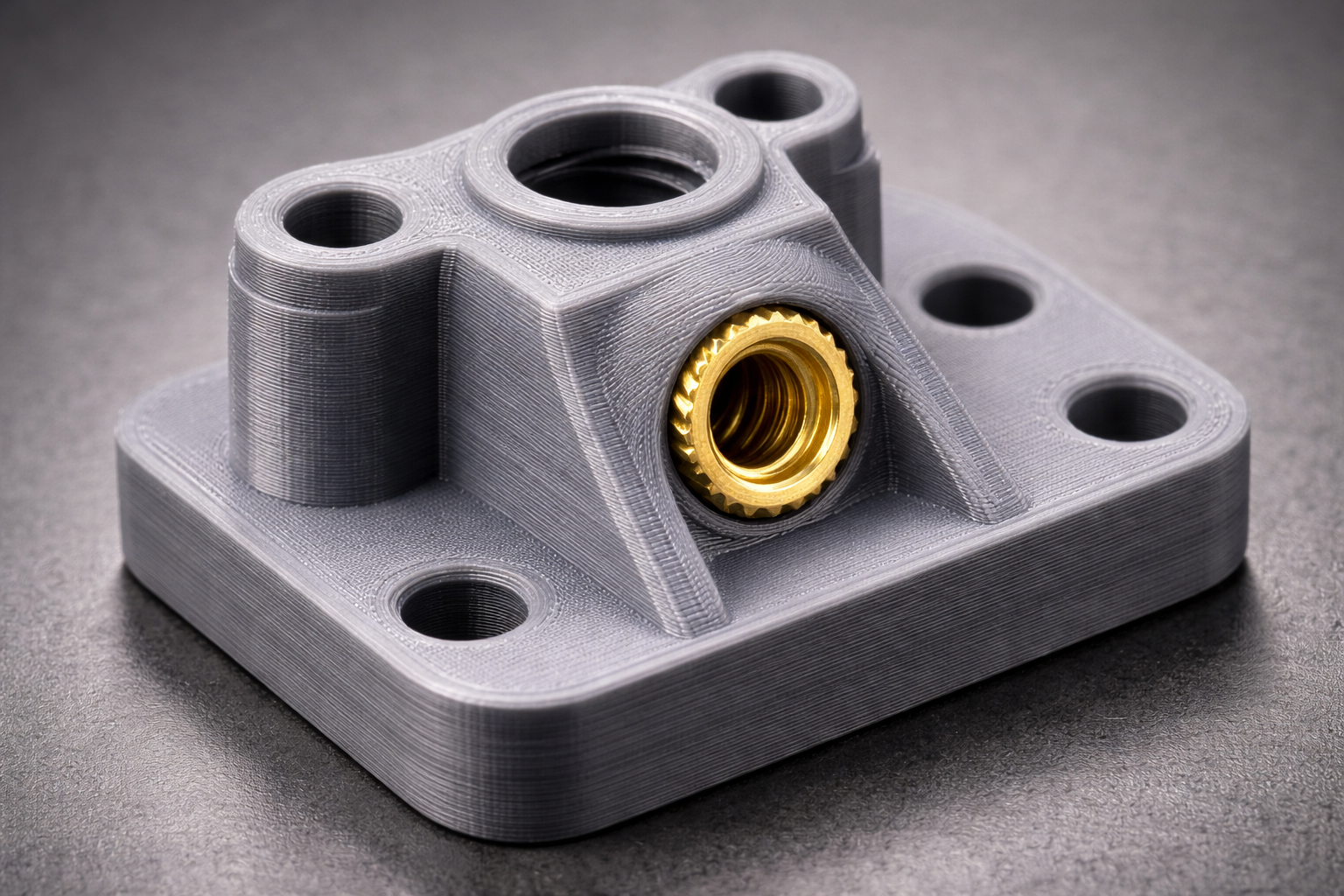

Threaded Brass Inserts

Durable, repeatable threaded connections for 3D printed parts.

We offer heat-set threaded brass inserts for components that require strong, reliable threads capable of withstanding repeated assembly and disassembly.

Threaded inserts significantly improve joint strength compared to printed threads, making them ideal for end-use parts, jigs, fixtures, and assemblies.

Benefits of Threaded Inserts

Increased thread strength and wear resistance

Suitable for repeated fastening and maintenance

Cleaner, more professional assemblies

Improved load distribution within printed parts

Typical aplications include but not limited to: Enclosures and housings, Brackets and mounting points, Jigs and fixtures, Structural assemblies and many more.

Multicolour Model Printing

Visually striking, functional models produced using multi-material and multicolour printing.

This service is ideal for applications where visual clarity, part identification, or branding is important — while still maintaining functional integrity where required.

Common uses include:

Assembly aids and visual guides

Branded components

Identification tags and labels

Demonstration and presentation models

Multicolour printing can also be used to differentiate features, interfaces, or moving components, improving usability and communication.

Materials We Offer

We currently provide our services using the following materials:

PAHT-CF

Nylon PA12

ASA

PLA

PETG

Each material has unique mechanical, thermal, and chemical properties.

Full specifications, recommendations, and technical data sheets are available on our Materials page.

Why Choose Us?

🇬🇧 UK-based design & manufacturing

🧪 Engineering-grade thermoplastics & CF composites

🔁 Consistent, repeatable production processes

🤝 Clear communication & practical engineering support

Ready to Start?

Send us your CAD files or project details and we’ll help you choose the right material, process, and production approach for your application.